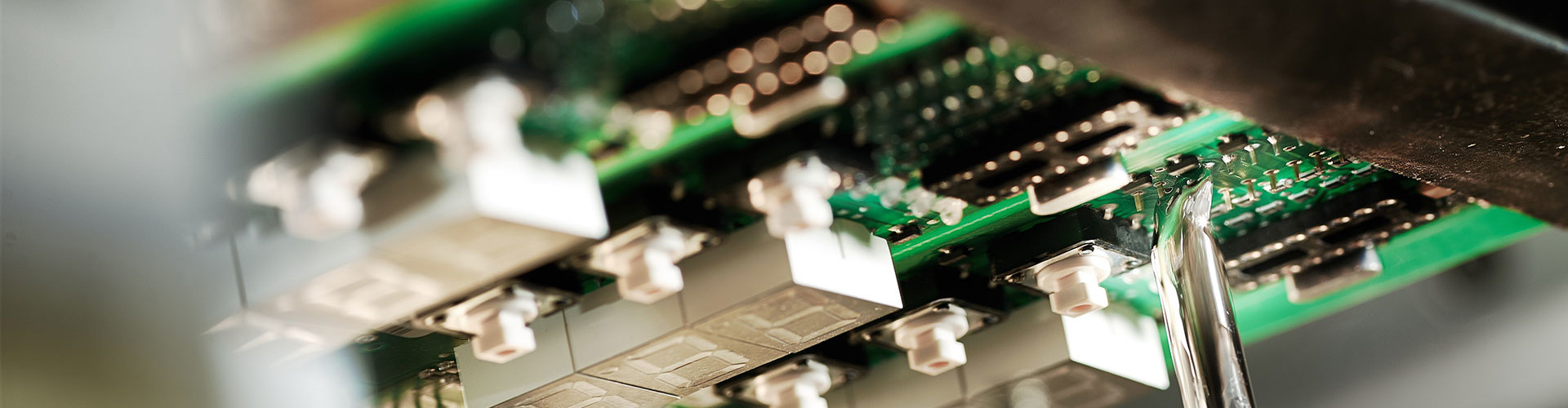

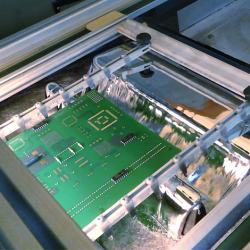

THT Assembly

Through – Hole Technology

The THT line, recently updated, allows the soldering (both tin lead and Lead free) of boards up to 450 mm wide with high speed and with the possibility of dedicated trolleys suitably protected according to the needs of individual customers and their products.

Casteltech also has equipment for cutting and forming THT components, for mechanical assembly and testing of boards.

The staff is constantly updated by IPC certified external professionals.

COMPONENT PREPARATION

- Equipment for cutting and preforming taped axial components

- Equipment for cutting and preforming loose axial components

- Equipment for cutting and preforming of taped radial components

- Equipment for cutting and preforming loose radial components

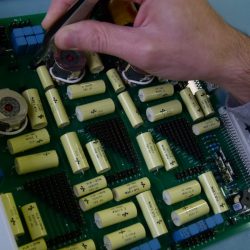

Component assembly

- ESD carousels

- Drawers for ESD components

WELDING

- 3 m of preheating

- Double wave

- Double titanium pocket for SNPB and LEAD FREE alloys

- Maximum board width 450mm

Revisions

- Weller WXP series welders and desoldering

- Mantis Viewer

- Green Light lenses

- Separate workstations and equipment for reviews with Lead Free and SNPB alloys

MECHANICAL ASSEMBLY

- Kolver electric screwdrivers with adjustable tightening torque

- Manual screwdrivers with adjustable tightening torque

- Torque meter

- Various tools help mounting

TESTING

- Electrical testing based on customer specifications

- Functional testing based on customer specifications