SMD Assembly

Surface Mounting Device

Casteltech is equipped with three SMD production lines, the first oriented towards medium-high volume production, the second more focused on small to medium volumes with high flexibility and technological sophistication with the possibility of electrical testing before assembly. The latest line purchased allows solder paste to be dispensed directly onto the board and components to be assembled immediately afterwards, without the need for screen printing foil.

The high performance of the oven (8 + 8 + 2 zones) allows to completely absorb the needs of the two assembly lines.

Production is supported by intelligent (Essegi Automation) humidity-controlled cabinets for component management and an AOI for automatic optical inspection of the boards produced.

The production process is completely traced by specialized software with control of the processing phases and production progress.

Casteltech also has a re-work machine (for BGA and QFN) for the repair of defective cards.

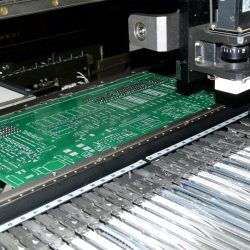

AUTOMATIC SCREEN PRINTING

- Zflex self-tensioning frames for 520x520mm and 524x524mm sheets

- Steel blades up to 500mm

- Automatic cleaning of the foil

- 2D control of the deposited paste

- Automatic pneumatic pushers

- Possibility to treat foils with nanotechnology

dispensazione pasta saldante con

valvola getting

- Dimensioni dei dot della pasta saldante: dai 0.25 ai 0.35 mm di diametro

- Possibilità di dispensare pasta saldante/colla conduttiva all’interno di cavità

- Controllo laser planarità pcb

- Controllo dimensioni dot dispensati

- Possibilità di dispensare resine e fluidi in generale

- THR e maggiorazioni di pasta saldante in maniera selettiva

- Campionature senza l’utilizzo di lamine serigrafiche

- Rework e reballing BGA

https://youtu.be/xCOa-63OcTo

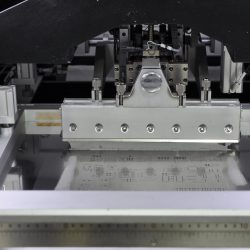

PICK & PLACE

- 476 spazi feeder da 8mm a 56mm

- Electrical and mechanical feeders

- Assembly of components up to 01005

- Electrical test

- PCB mounting from 50x50mm up to 500x500mm

- Automatic pneumatic pushers

REFUSION WELDING

- Reflow oven 3600mm length

- 8 + 8 zones + 2 cooling

- Mesh and chain

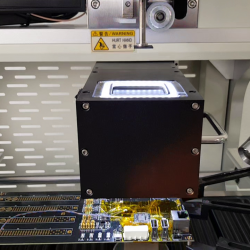

AOI OPTICAL INSPECTION

- I3D technology

- Check:

- presence absence

- rotations

- written

- solder meniscus

- planarity

- heights

- tombstone and other defects

- presence absence

- rotations

- written

- solder meniscus

- planarity

- heights

- tombstone and other defects

REWORK STATION

- Optical centering prism with separate top and bot lighting

- PCB preheating with IR BOT panel

- TOP nozzle temperature adjustment

- Motorized Z axis movement

Dispensazione pasta saldante jetting

- PCB with cavity;

- Chiavette usb key Type-A;

- Token usb e montaggio componenti elettronici in una cavità, incassati, sotto al piano.